Bow Ties Sydney, Australia - Le Noeud Papillon - Specialists In Self Tying Bow Ties

Google Le Noeud Papillon's Blog

Translate This Blog

Saturday, April 20, 2024

Wednesday, April 10, 2024

Thursday, March 21, 2024

Monday, March 18, 2024

Regular Sales Keeps Us At Our Cutting Table - Le Noeud Papillon Of Sydney - Artisan Tie Makers Of Distinction

Recent Work By Le Noeud Papillon - Text +61413140994 To Schedule And Appointment And Free Style Advice

We are here to serve you, to make you look your best when you need to look your best. Weddings, celebrations, heading out on the town and wanting to make an impression - we strive to make you the belle of the ball.

And we are happy to advise you on matters of style - free of charge - day or night - simply text +61413140994 .

Thursday, February 15, 2024

The Le Noeud Papillon Portrait Competition Has Now Ended

Firstly let me say thank you to everyone that contributed to

the portrait competition. Each and every work took up your time which I am

extremely grateful for. It was shaping up to be a dismal failure, in the end,

worked out to be one of the best if not the best competition to date.

1.

Clementine Blackman

2.

Timothy Farley

Each of the runners up have a voucher for $500.00 AUD

I would like to say that the runners up were hard to choose

as I had loved the intricate work of Curran Chai, the work of Ineke was

striking, young Marco Bialek who sketched his father in Mallorca on the

occasion of his 50th birthday. The 1980’s feel of Henry Gair, the

yuzen bow tie of Barnabas Bako, the hint of Joni Mitchell in Kristine’s sketch

with beret and silk scarf. The list goes on. I loved all of them.

And so for each of you that submitted outside of the

winners, you will receive either a black bow tie from us for the men, for the

ladies, a silk scarf. Please make contact on +61413140994 to claim your prize

for your contribution.

And, thank you. I was so pleased with the final result.

Bravo to all of you.

Wednesday, October 25, 2023

Tuesday, October 24, 2023

Have You Ever Thought About Another Life You Might Have Led?

Sometimes we meet at junctions in the road, and we stop to look back on the road travelled. Someone once described to me life like a roll of toilet paper, the closer you get to the end, the faster it goes. As time goes by, we become more and more entrenched in our lives and it becomes harder to change, much easier just to accept what is.

Yesterday I was with my trainer, Les, he’s edging on 80 but still starts his morning with 500 push ups. When I am on the ground and I can’t get more out of my core, he kicks me. I kind of like that. In an age when everyone is so precious, it’s nice to pay someone to kick you when you are down.

In order to attempt more stamina and to build to a sort of crescendo of exercise I decided to play Boléro on my speaker but despite it motivating me, it took me back to a place I had forgotten.

It was a wet summer and in December I drove down towards Tumbarumba, a place that’s name means “walking on hollow ground”. It is about 6 hours from Sydney heading south and sits at the foothills of the Snow Mountains. To get there you go through the most famous Australian town for apples, Batlow. It was a cold summer’s night, and the country was green from a wet summer. A full moon had bathed the landscape silver, glimpsed between the trees and at certain vistas along the way, shining light bouncing off the white sails that protected the apple orchards. I had a cigarette out the window of my Audi 80 and Ravel’s Boléro blaring through the speakers. I was on my own and could not be happier. I was an agricultural economist in the second last year of my degree.

That summer I was on my own for most of it. Other kids were off having the time of their lives, but I had to get through three to four months of working on farms in order to earn my degree. But it wasn’t the work that motivated me that summer, it was the times I spent on my own in the house I occupied. I had a car full of books and of music and a journal in which to write and for that wet summer, on my own every night, I think for the first time I fell in love with my own company. I would drink red wine on my own at night, listen to a live recording of Bob Dylan, classical music, Fleetwood Mac, Dire Straits, the Beatles. I would read Tolstoy and Hemingway and the like. I think perhaps now looking back it was probably a little cliché. But as a young person discovering these things with time on your side it was such a wonderful pleasure. And then there was the classical music, again, probably cliches, but the most prominent of them would be Chopin’s Nocturnes, Tchaikovsky, Lakme’s Flower Duet and of course Ravel’s Bolero. A handful of classical music CD’s that I would play over and over with nothing much else to do after a day on the land.

I almost don’t remember the work. There was pruning that summer from memory. And grafting. I did not care for the work but in that way that Tolstoy glorified country life, I came to see it as a sort of idyll even if the human stories you heard and the characters you met did not stand up to that image, some of them more Dostoyevsky than Tolstoy.

And I wrote. And I had such strong and powerful dreams that cold wet summer. And I wrote.

Music and perfume. They are such strong ways of conjuring memory.

All it took to recall the flyfishing, pruning the vines, the sound of the farm manager shooting at birds on the dam in the late afternoon, the tractors, the tool shed, those drives at night on the country road, ranging from silver in the moon to complete darkness when there wasn’t one. The stars, the furnace fire drying your wet socks – all of it from hearing Boléro again. A young man with ideas and time on his hand.

My father turned 80 last Sunday. Not long ago he was talking to me one morning and he said “I can recall lying in my bedroom as a young boy, I used to read Greek mythology and ancient Greek history and when I stared at a certain bit of plaster on the wall, I could make out warriors and the battles as if I was there. And if I think hard enough, I can still see myself right there in my bedroom. It feels so clear to me.” In a small moment that little boy was now 80. He was thinking of his life lived, his choices. He had led what I believe is a good life. Certainly, more wholesome than my own. A product of post WW2. He had done very well in life, but regardless, he was old now, the bulk of his life behind him.

At a cemetery in La Perouse some years earlier my brother and I had walked around mid-winter with my late grandmother. As she walked down one of the pathways, she pointed to either side of the row and told us who they were to her – her uncle, her mother, brothers, her cousins. All gone. It was a cold day etched in my memory. She passed a few years later.

The Boléro is my most favoured work of Maurice Ravel thought Pavane For A Dead Princess is a close second. Boléro reminds me of life, it is the building of a crescendo, from the soft beginnings of a snare drum which in life are infancy and the child developing, to the transfer of the melody that began in childhood moving beginning to change, passing over to the flute, the clarinet, the oboe and finally onto brass. The is the ingenious composition that seems simple, but is in parts rather complex – a wonderful metaphor for life itself. The heartbeat stays with the composition throughout, like the heartbeat that and pulse we keep ourselves. It keeps us focused and engaged, we are alive, we are moving through time. And like life, we build slowly and with gaining intensity and tensions to crescendo of our lives before a climax and then, finally, the closing of the curtains.

And so, as I listened to it again and again yesterday as I went about my business, I conjured up all that had passed, all that I might have been had I taken a different direction. Had I married that wonderful Danish girlfriend I had, had I struck up a conversation with that ginger beauty at the local supermarket in Tumbarumba that wet summer, had gone onto trade derivatives in commodities as an agricultural economist, had I taken any other path other than the one I chose.

So today I simply want to ask you, have you ever thought about another life you might have led? And perhaps whilst you ponder on it, play Ravel’s Boléro.

Saturday, October 21, 2023

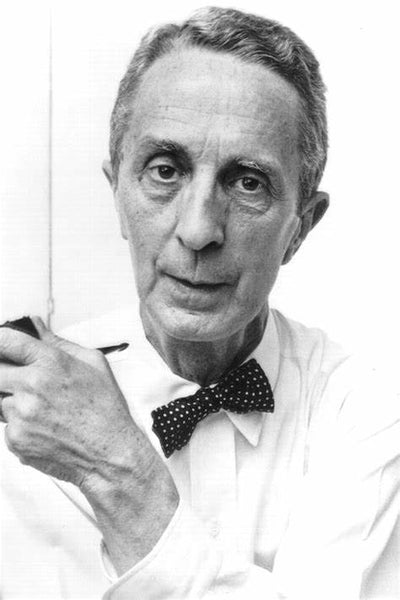

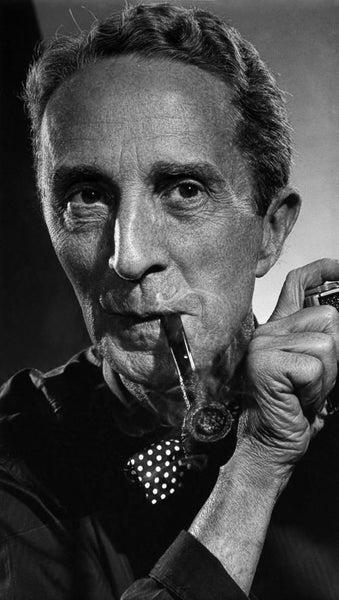

Norman Rockwell – The Idyllic American Life

Recently I was lying on my bed one Saturday afternoon depressed about the state of the world and the fact that business had been slow for the time of year.

I was on YouTube when I found a documentary when I decided to look up Norman Rockwell, one of those names that you often hear in movies and culture but as an Australian it doesn’t mean so much to you that it passes your ears and you think no more of it.

But this particular Saturday I was interested in knowing more, so I clicked on this PBS American Masters documentary and sat back to pass the afternoon in a quiet space.

Norman Rockwell’s influence on American culture runs surprisingly deep as I found out. For an illustrator who never really saw himself as an artist, he transformed the national psyche and was perhaps one of the most influential artists of the 20th Century in the United States. His pictures depicted an idyll of American life, much the same as a toile fabric does for Europeans.

Born in New York city in 1894 his career spanned much of the 20th Century until he passed in 1978. His observations of American life, coupled with his positive outlook on American life made him endeared to the entire country. Despite being an illustrator, his meticulous attention to detail in his works have earned him a place in the art world, probably more so posthumously.

He began sketching from an early age and chose his path early on. By the time he was 14 he was enrolled in the New York School of Art and by 19 he was the art director of the Boy Scouts of America – an impressive title for such a young and budding artist.

In 1916 he took some drawings down to the Saturday Evening Post and much to his delight the drawings he submitted were accepted. As one biographer commented, this was like winning an Oscar on the first time you made a film, an achievement that would then lead to a remarkable 47 year association with the Post where he would create iconic covers that today are revered the world over.

Probably his most famous group of artworks were based on Franklin D. Roosevelt’s 1941 State Of The Union address in which the rousing words of Roosevelt then in the grip of the 2nd World War, gave Americans hope and courage in the face of adversity. Roosevelt claimed that American’s were entitled to four key freedoms, Freedom Of Speech, Freedom Of Want, Freedom Of Worship, Freedom Of Fear. These were to inspire Rockwell to make an artwork of each, resonating with Americans so much so they played a crucial part in bolstering the resolve and the morale of Americans through the war.

His most famous of these was Freedom Of Want, a depiction of an unadorned American family enjoying a splendid Thanksgiving dinner where three generations of Americans enjoy an idyllic meal together where light and texture give rise to a feeling of homeliness, gratitude and abundance. This was the American dream right down to its core and would become one of the defining artworks of the 20th Century.

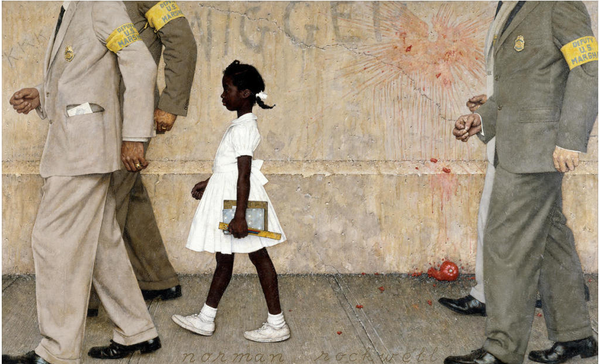

In later years Rockwell came to be disillusioned with the American dream, he was disturned by segregation in the United States and in the 1964 his artwork “The Problem That We Live With” came with criticism, he was loved for his American dream, he was less loved when he pointed out racial divides and what came to be his truth – that the American dream was perhaps just that – a dream.

In one of his final portraits Rockwell finally comes to accept his place in American art, his self portrait reflects an image of himself that is in some ways void of personality, but his message is best conveyed by those artists portraits that are pinned to the side of his canvas as he paints at his easel, they are Rembrandt, Picasso, Van Gogh and Durer. These are his icons, and this is how he sees himself.

As the world gets crazier still, with wars raging in Ukraine, with Israel poised in invade Gaza in retaliation to the most heinous massacre by Hamas terrorists, the American Dream and the ideal of a better world should be held up again to us as a mirror, of a time where what we aspired to was not bloodshed and war, but the four pillars of freedom.

And, of course, Rockwell was an avid bow tie wearer, he wore batwings that I will soon attempt to replicate, not to slim and certainly not fat. He is one of the great bow tie wearers, and perhaps one of the more interesting characters of the 20th Century.

Wednesday, October 4, 2023

Hugh Stewart - Photographing Australians

I met Hugh Stewart ( INSTAGRAM ) in Paris 16 years ago and we got along quite well. He and his partner Emma had a baby daughter, her name was Matilda, and I recall that at the time they left Paris he had asked me to pick up a plaster of Paris they had done of their daughter's tiny arm.

Hugh and I stayed in contact and occasionally I would bump into him and I had asked him on several occasions if I could either use his services to shoot our customers in their workplaces or else to get my own portrait done.

Hugh has worked on many different film sets and been sent all over the world to photograph celebrities from Johnny Cash, Clint Eastwood, Robert Hughes, Leonardo Di Caprio and many many others - they are not hard to find on google. But it is still life photography that also gets me. He just does it so well and he has this style about his photos, a certain rustic nature about them, slightly muted, well worn, something, akin to his own demeanour, idiosyncratic voice, worn shirts of muted hues, a dishevelled look, but nonetheless clean. Slightly smudged spectacles that could do with a clean.

It finally became possible for me to get photograph myself, because he has opened up a new service just off Queen Street in Woollahra. I am happy to say that after 16 years I finally got to sit in front of his camera and I am extremely happy with the result.

Have a look at his Instagram and if you are Sydney side, or near Byron Bay, you can catch him in his respective studios for a sitting.

It Still Thrills Me To See Our Bow Ties Roam Around The World

This week our bow ties found themselves in Paris, France, in Uluwatu Bali and in Norway. It is testimony to the quality of our bow ties and that each of those who wore our bow ties this week would attest to the moniker often given to us of "the world's best bow ties".

We asked Google's new AI 'Bard' the same question and happily we came back first on their list. But we only have that moniker because of our elegant customers who continue to show the rest of society how wonderful and effective the hand tied bow tie is at revealing panache, style, sophistication and everything that is good about menswear and the finer points of dressing well.

Thank you to Hugo, Alex and Richard for keeping the sartorial flame burning. We look forward to seeing your next posts.

Wednesday, August 23, 2023

Supporting The Wayside Chapel - Thank You For Your Donations

I have to thank our customers, one in particular, because we managed to raise 2500 aud or the Wayside Chapel winter appeal. Of course, I provided the product, but it was you guys who turned it into cash which could be donated. I will be running another of these sales towards the end of the month, no long now, and we will sell down all that remains of this month’s cut, but this time I intend to hold back on black tie and a few other collections.

Two weeks ago, I got a call from Wayside, their representative Samantha Jackson, their philanthropy manager. She was grateful for the donation and concurrently invited me in to see the facilities and at the same time explained that for them private donations are essential because it allows them to be more agile than often government funding allows for.

Yesterday I met up with both Samantha and Gabby on site. The Wayside Chapel is on Hughes Street in Potts Point, effectively Kings Cross – well it most definitely feels like Kings Cross, and it is a stone’s throw from it.

The building has been the home of The Wayside Chapel since Reverend Ted Noffs and his wife embarked on their project in the 1960’s to provide love and compassion and social justice to those living under difficult circumstances in the Kings Cross area.

For those of our readers from overseas, Kings Cross in Sydney is the red-light district. It has always been colourful, but in recent years this area, Potts Point included, has been increasingly gentrified and the area has over the years become an interesting melange of the rich and poor co-existing in the same area, for example, within 50 metres of Wayside is one of the more elegant stores offering glassware and objects for the home.

However, it wasn’t like that when the Wayside began. It was an area filled with homelessness, drug addiction, poverty and mental illness. In fact, it all goes hand in hand – and part of that has shaped the character of the area for decades. The Wayside Chapel intended to be beacon of hope or as Samantha explained, the founding ethos is “love over hate”. Pretty simple really. And it seems to really play out there in everyday interactions between those that use the services that the Chapel offer and those that provide them. There is a sense of “anything goes” at Wayside, you are loved and respected no matter what gender you identify as, what religion or lack of religion you have, what your sexual preferences are, whether you are addicted to drugs and alcohol or not, the colour of your skin, whether you are homeless or not, your mental state of mind – none of it matters, all of it is accepted. And so, it has become a hub for so many interesting characters that come and go.

Upon the moment I arrived I was met by Gabby, an attractive younger woman I imagine could be in any industry she chose. She presented very well, well mannered, well groomed, simple, easy to talk to. Her clothes were earthy, a grey woolly vest, white t shirt, a black skirt and converse shoes. She explains that Samantha is running late, she’s just around the corner, and then we are interrupted by Andrew. He begins his monologue about Wayside and how he uses the services here, his background in addiction, his sexual preferences, the drugs he hates (heroin) and the ones he could easily go back to (cocaine). It is very amusing and within another minute another man was standing on top of a bench poising himself in a superhero stance and saying something that was between a declaration and a mumble. Very interesting characters indeed. In fact, it was like a portal back into the old Newtown, and the old Cross. Many of these characters are less prevalent these days, and a sort of hostility has brewed. The new guard seems to want the old guard out.

But The Wayside continues deliver services to those that have fallen through the cracks and really need somewhere to belong, that society has done everything to avoid confronting. Those are the words of Samantha, and she explains that they help with even things like creating bank accounts for those that have no identification. It is hard to understand what that is like for those of us that live within the confines of what one might consider “a regular life”. We have tax file numbers, companies that are registered, gas and electricity bills in our names and so on. These people are off the grid, often entirely. The average homeless person that visits the Wayside walks up to 28 kilometres a week just to find places to stay the night, between shelters and locations across the city like under bridges and in open parks. Samantha was a donor to Wayside before she began working here about a year and half ago, around the same time Gabby joined, she wanted to work somewhere that aligned with her values and where she could see the results of what her daily work accomplished. And she says she gets it in spades. That every day she goes to work she sees meaning and purpose in what she puts her hand to. Gabby’s story is similar. She was a graphic designer by education but then working in the advertising industry on products she found didn’t fit with her values she decided to throw in the towel. She says she loves what Wayside stands for and that the people who raise money for Wayside, the Wayside front liners and the people that frequent Wayside all interact to form a very unique community. It also means she feels that she can see the difference she is making on a daily level.

And one of the reasons that Wayside is so successful is that it doesn’t try to fix people and instead allows them to make their own decisions. If they want to remain addicted to drugs, Wayside doesn’t try to sop them. If they find it too hard to put a permanent roof over their head, Wayside doesn’t push them. Wayside merely tries to give them the services that are often denied to such people. When you walk 28km a week then you’d want to get that ingrown toenail fixed, so the doctor comes past to help with that. If you are the victim of domestic violence, they will help you start a fresh page. And on a more basic human level, if you are simply lonely and need connection, this is a form of home, especially for the homeless. You can take a hot shower, check in with the notice board, listen to live events each day of the week like poetry or jazz.

And yes, there is a chapel. It was until recently run by the Reverend Graham Long but in recent times it has been taken over by Pastor Jon Owen. It remains committed to the ethos of Love Over Hate and continues to hold a service each Sunday, which is open to all.

|

| Samantha, myself and Gabby in front of the weekly entertainment board for The Wayside Chapel |

Livin’ Better Now, Coogi Sweater Now

When Coogi started in Torak in 1969 it was known as Cuggi. It wasn’t until the mid-1980’s that the name changed to something more indigenous Australian sounding. And it wasn’t until the early 90’s that it really gained traction in the US market with Biggie Smalls rapping about them amongst others.

Coogi’s success was built on quality mercerised cotton and merino wool being woven in a unique array of colours and weaves in 3 dimensions to create striking fabric which is imitated by others, but which never quite seems to reach the original production.

I probably need to stop here and make a note. Cuggi and Coogi up until the early 2000’s should probably be separated from what Coogi is today. The company was founded by Jacky Taranto and in those days and under his stewardship the company was focused on producing high quality knitwear for the Australian market. This Cuggi / Coogi is a different company to today’s Coogi. In those days, and I possess a vintage one with the original care labels, they were made in Australia and so too was the fabric woven here. This makes a big difference, a sense of control and hand in the product that can sometimes mean the difference between something magical and something replicable.

Speaking of which and on a side note; one of the most famous people said to have worn Coogi sweaters was Dr Huxtable in The Cosby Show. So much so that Coogi could sometimes be referred to as The Cosby Sweater. This is not true though. In fact, a Dutch designer named Koos Van Der Akker is credited with designing a good deal of Bill Cosby’s sweaters.

Back to the story. So, the reason I mentioned the two Coogis was because I want to remind our readers that some of the best of what companies produce comes from the authenticity of those that create it. There is a reason that Coogi is featured in the Smithsonian National Museum Of African American History and Culture for its cultural significance in shaping American culture - it is original. Lyrics by artists such as Biggie Smalls who raps ‘every cutie with a booty bought a Coogi’ exemplify how it became part of the lexicon of rap with the rise of artists such as Tupac Shakur and Snoop Dogg also wearing these unique sweaters. And it is the old Coogi that these guys were enamoured with. The Australian production, unique, referencing in a sense Australian indigenous culture, made from Australian yarns sourced by Taranto and his team, carefully woven to deliver, even to this day, a product which is still unmatched by others who are pursuing the same line.

Admittedly, the cut is a little odd at times and part of me wishes that I could go back in time and re-tailor these garments to get a more fitting result, but another part of me thinks they should remain exactly as they are. They are pieces of art that should not be disturbed. In Australia we have spent the last three decades outsourcing production as much as we could. Let the Chinese, Indonesians and Vietnamese weave our fabrics, okay now let them make our product too. So much so that eventually all that designers do in this country is press send on an email and then wait for the freight forwarder to tell them the container is in port. This is my least favourite thing about fashion and designing. Once, when I began my business, an artist friend of mine sent me a WH Auden quote, I have never forgotten it – “a poet’s hope; to be like some valley cheese, made local, prized elsewhere”. It serves to remind me often of what it is to make an authentic product. To have a hands on approach, to make something which is unique right down to the fibres you used. It is for this reason that I have a profound respect for Taranto and the early days of Cuggi / Coogi. This is a brand that epitomises the best of our country and what is has to offer. And yes, we have given so much of it away but then perhaps this paves the way for the next generation to pursue something for themselves - the next Coogi.

I would love to know where the fabric was woven and the techniques deployed but I gather that the last time anything was woven in this country it was a different and more disconnected world. What remains of fabric weaving in Victoria is now merely a tiny reference point to a country that was once far more active in turning our raw product into cloth. It was once said, and how long ago that time seems now, 'that Australia rode on the sheep's back'.

Today Coogi is headquartered in New York. It seems to have lost any authenticity. After Taranto sold the company when it was in financial difficulties in the early 2000’s the company changed hands a few times, nothing which I tracked with any enthusiasm. It’s current owners sell it very much to black American culture, it lacks any real authenticity and reference to Australia. It is effectively dead in the water because it has lost that founders touch. Until it comes back to Australia it will never be anything of great importance, for it is only the authenticity of the country and province of origin, like Camembert cheese is to French monks from the village of Camembert, or what the Barossa Valley is to Australian wine, that invokes in us that magic that makes you sigh - this is the real thing.

And so, in conclusion, I finally own a Coogi sweater, I bought a vintage one. It even says CUGGI on it. It is magnificent, textured, layered, colourful, cosy, vibrant and very comfortable to wear. I support local production, I hope that we have more Coogi’s develop out of our country. We have so few.

Friday, August 18, 2023

The Exhibition Of Miniartextil Running Until September 3, Lake Como, Italy

What is fiber art? (We in Australia spell it as fibre) . It’s art made of textiles. Since the beginning of weaving textiles they have been used to create patterns. You might consider that art, it is in fact art. But over the past century a movement of artists steered away from traditional textiles prints and began to explore the medium in three dimensions, in textures and colours, weaves and patterns from a wide and varied range of techniques including knitting, embroidery, tapestry, felting and more.

What these techniques and mediums in fibre create is also wide an varied. From wall mounted tapestries to sculptures made of fibre, it is a unique world that steps away from most other means of creating art. Sometimes messages are embroidered or printed onto mediums, sometimes woven. Sometimes the form is an abstract expression of a shape or object conjured by the artist.

You may have seen our Instagram post from just after Christmas where I explored the winter exhibition in Lake Como, or perhaps you then saw my visit to the Palazzo Mocinego in Venice or to the home of Mimmo Totaro, one of the founding fathers of fibre art in Europe.

And the reason I mention all of this is because there is an exhibition currently running until September 3rd in Como. It once again explores artists from Asia, Africa and Europe across a broad variety of expressions in fibre art. By all accounts it is an interesting exhibition.

Exhibition: Lake Como, Via Odelscachi – runs until September 3rd

You can read more about the exhibition here.